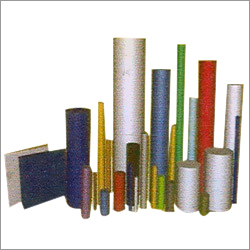

Cast Nylon Rods

Cast Nylon Rods Specification

- Casting Process

- Gravity Casting

- Usage & Applications

- Gears, Bearings, Rollers, Conveyor Parts, Wear Pads, Machine Parts

- Load Capacity

- High (Specific to Size & Application) Metric Ton

- Product Type

- Cast Nylon Rods

- Surface Finishing

- Smooth

Cast Nylon Rods Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 15 Days

About Cast Nylon Rods

Taking the benefits of our modern infrastructure facilities, we are engaged in manufacturing and supplying a qualitative range of Cast Nylon Rods. We manufacture these rods using optimum quality cast iron and nylon procured from our reliable and authorized vendors. Owing to features like compact design, high impact resistance and excellent strength our Cast Nylon Rods are applicable in heavy-duty bearings, gears, rollers and bushings. We offer these rods in different shapes and sizes as per our valuable clients need.

Exceptional Engineering Performance

Cast nylon rods offer a compelling combination of mechanical robustness, impact resistance, and low friction, making them suitable for stringent industrial applications. The excellent balance of tensile strength and hardness ensures durability, while their ability to resist moisture absorption and provide electrical insulation enhances operational stability across varying environments. Their high load capacityadapted for specific sizes and usesmeets the demands of intensive applications.

Versatile Applications Across Industries

These rods are extensively used for manufacturing gears, bearings, rollers, conveyor components, wear pads, and precision machine parts. Their adaptability allows for customization in diameter and length, ensuring optimal fit for both standard and unique operational requirements within sectors such as manufacturing, automation, and processing industries.

FAQs of Cast Nylon Rods:

Q: How are cast nylon rods manufactured and finished?

A: Cast nylon rods are produced using the gravity casting process, which provides a smooth surface and consistent material quality. This method allows for manufacturing rods in a wide range of diameters (16 mm to 300 mm) and customized lengths up to 3 meters, ensuring precision and reliability in performance.Q: What benefits do cast nylon rods offer compared to traditional materials?

A: Cast nylon rods deliver advantages such as excellent machinability, high tensile strength (80 MPa), good impact resistance, low friction, and superb electrical insulation. These properties combine to reduce wear and maintenance while increasing efficiency in high-performance industrial applications.Q: When should cast nylon rods be selected over other engineering plastics?

A: Cast nylon rods are particularly suitable in scenarios where high load capacity, smooth surface finish, dimensional stability, and electrical insulation are required. Their resistance to moisture and good impact strength make them ideal for demanding, high-wear environments.Q: Where can cast nylon rods be used effectively?

A: These rods are effective in a multitude of industrial settings including the manufacturing of gears, bushings, rollers, conveyor systems, wear pads, and machine parts. Their applications extend across sectors such as automotive, food processing, packaging, and general machinery.Q: What is the typical process for ordering custom-sized cast nylon rods?

A: To order custom sizes, specify the required diameter (between 16 mm and 300 mm) and length (up to 3 meters). Suppliers and manufacturers in India offer flexibility to accommodate special dimensions, ensuring a tailored fit for your engineering needs.Q: How does the moisture and electrical resistance of cast nylon rods benefit users?

A: Their low water absorption (1.21.7%) ensures dimensional stability in damp conditions, while excellent electrical insulation protects components in electrically sensitive environments, making these rods a reliable choice for a wide range of applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Nylon Products Category

Cast Nylon Products

Price Range 1000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Other, Cast Nylon Products

Usage & Applications : Gears, Bearings, Bushes, Rollers, Pulley wheels, Engineering components

Material : Other Ductile Iron, Cast Nylon

Weight : Customizable

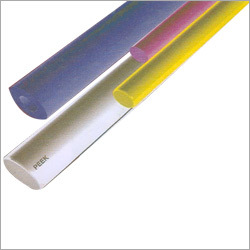

Nylon Rods

Price Range 1000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Other, Nylon Rod

Usage & Applications : Bearings, Bushings, Gears, Rollers, Insulators, Machine Parts

Material : Other Ductile Iron, Polyamide (Nylon)

Weight : Varies with dimensions (customized)

Send Inquiry

Send Inquiry