Nylon PP Sheet

Nylon PP Sheet Specification

- Heat Resistance

- Up to 110C

- Leak Protection

- Moisture and chemical resistant

- Color Pattern

- Solid

- UV Resistant

- Yes, available with UV stabilizer

- Melting Point

- 160C (Polypropylene), 220C (Nylon)

- Plastic Type

- Thermoplastic

- Surface Finish

- Smooth

- Type

- Nylon PP Sheet

- Material

- Polypropylene (PP) and Nylon

- Shaping Mode

- Extrusion Molding

- Length

- Customizable as per order

- Weight

- Varies by size and thickness

- Plastic Molding Type

- Sheet Molding

- Size

- Standard and custom sizes available

Nylon PP Sheet Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Nylon PP Sheet

We have acquired a leading position for ourselves in this domain by manufacturing and supplying an exclusive range of Nylon PP Sheet. These sheets are manufactured under the strict supervision of our expert team using finest quality raw materials. These are used to fabricate ducks and hoods by welding and heating processes. Our Nylon PP Sheet is highly appreciated by our clients for its high strength, ability to withstand high temperature and durability. The orders we get from the clients are properly noted and delivered to their destination within the specified time without any damages.

Superior Heat and Chemical Resistance

Nylon PP Sheets are engineered to endure challenging environments, thanks to a blend of heat resistance (up to 110C) and robust chemical/moisture protection. This makes them ideal for applications in industries like chemical storage, food processing, and outdoor installations where durability is paramount.

Customizable Solutions for Diverse Applications

With both standard and tailor-made size options, our Nylon PP Sheets meet a wide spectrum of project requirements. Whether you need custom lengths, varying thicknesses, or unique color patterns, our sheets can be manufactured according to your specifications for maximum flexibility.

FAQs of Nylon PP Sheet:

Q: How are Nylon PP Sheets manufactured?

A: Nylon PP Sheets are produced using extrusion molding, a process where thermoplastic materials like polypropylene and nylon are melted and formed into sheets. This technique ensures high consistency, strength, and a smooth finish.Q: What are the primary applications of these sheets?

A: Due to their durability, heat resistance, and chemical protection, Nylon PP Sheets are suitable for packaging, automotive parts, industrial linings, chemical handling equipment, and outdoor signage, among other uses.Q: When should I choose a sheet with a UV stabilizer?

A: Opt for Nylon PP Sheets with a UV stabilizer if the material will be exposed to direct sunlight or outdoor environments. The UV treatment extends the products life and prevents color fading and material degradation.Q: Where can Nylon PP Sheets be installed?

A: These sheets can be installed in various environments, including indoor factory settings, outdoor construction sites, and chemical storage facilities, thanks to their resistance to moisture, chemicals, and changing weather conditions.Q: What is the benefit of customizable length and size?

A: Custom sizing ensures each Nylon PP Sheet fits your applications exact measurements, reducing waste and maximizing efficiency during installation and use.Q: How do the melting points of polypropylene and nylon affect sheet performance?

A: The distinct melting points (160C for polypropylene and 220C for nylon) offer thermal stability across a wide temperature range, making the sheets suitable for processes or environments where high heat is a concern.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Products Category

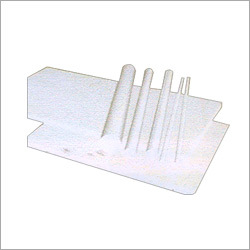

Nylon Uncoiler Mandrel

Price Range 1000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Color Pattern : Solid White

UV Resistant : Yes

Tensile Strength : 70 MPa

Type : Uncoiler Mandrel

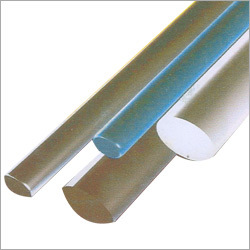

Polyethylene Terephthalate Nylon Rod

Price Range 1000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Color Pattern : Solid

UV Resistant : Yes

Tensile Strength : 80100 MPa

Type : Nylon Rod

Nylon Cutting Boards

Price Range 1000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Color Pattern : Solid

UV Resistant : Yes

Tensile Strength : Good (as per nylon standard)

Type : Cutting Board

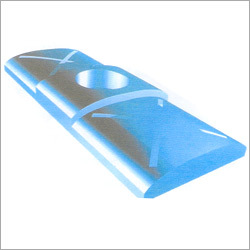

Nylon Slipper Pads

Price Range 1000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Color Pattern : Solid

UV Resistant : Yes

Tensile Strength : 65 MPa

Type : Slipper Pad

Send Inquiry

Send Inquiry