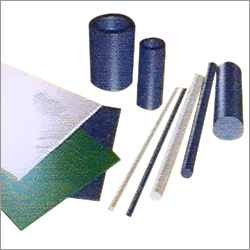

Nylon UHMWPE Roller

MOQ : 10 Pieces

Nylon UHMWPE Roller Specification

- Diameter

- 89 mm to 159 mm

- Material

- Nylon, UHMWPE (Ultra High Molecular Weight Polyethylene)

- Dimensions

- Length: 200 mm to 2000 mm (customizable)

- Technique

- Injection Molding, Machining

- Standard

- ISO, DIN, Customized

- Belt Width

- 400 mm to 2200 mm

Nylon UHMWPE Roller Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Nylon UHMWPE Roller

Backed with know-how and comprehension in this domain, we are counted amongst the foremost manufacturers and suppliers of Nylon UHMWPE Roller. This roller is manufactured using optimum quality material and advanced technology under the supervision of our quality controllers. Our Nylon UHMWPE Roller has some salient features like long functional life, flexibility and effective noise reduction. Owing to these features this roller is used in coal, chemical, electricity, grain storage, ports, slat and other industries. We offer this range of roller at an affordable price to our customers.

Engineered for Industrial Excellence

Combining the advantages of Nylon and Ultra High Molecular Weight Polyethylene (UHMWPE), these rollers are built to withstand harsh operating conditions. Their design ensures a low coefficient of friction and significant resistance to abrasion, making them an ideal choice for heavy-duty conveyor systems across various sectors.

Customizable to Project Requirements

We offer extensive customization, including length, diameter, and belt width compatibility. Whether you follow ISO, DIN, or require bespoke dimensions, our engineering team leverages injection molding and machining to deliver rollers tailored to your precise operational standards.

FAQs of Nylon UHMWPE Roller:

Q: How are Nylon UHMWPE rollers manufactured?

A: Our Nylon UHMWPE rollers are produced using injection molding and precision machining, ensuring accurate dimensions and consistent quality. This approach allows for complex shapes and custom sizes to meet specific application needs.Q: What benefits do Nylon UHMWPE rollers offer over traditional metal rollers?

A: These rollers feature low friction, excellent wear resistance, and are significantly lighter than metal alternatives. This reduces energy costs, minimizes wear on belts, and extends the service life of both roller and conveyor components.Q: When should I use a UHMWPE roller instead of a Nylon roller?

A: UHMWPE rollers are especially suitable for environments requiring superior chemical resistance and extremely low friction, such as in mining and food processing industries. Nylon rollers perform well in moderate load and temperature conditions.Q: Where can these rollers be used effectively?

A: Our rollers are ideal for conveyor systems in industries like mining, food processing, logistics, packaging, and more. They help improve efficiency anywhere material handling and transport are crucial.Q: What customization options are available for these rollers?

A: Dimensions such as length (200 mm to 2000 mm), diameter (89 mm to 159 mm), and belt width (400 mm to 2200 mm) can be tailored to specific requirements. Standards including ISO, DIN, or custom parameters are available on request.Q: Describe the main process steps for producing an order of these rollers.

A: The process typically involves consultation to determine specifications, selection of suitable materials (Nylon/UHMWPE), fabrication via injection molding and/or machining, thorough inspection to meet quality standards, and global shipment from our India-based facility.Q: What advantages do clients gain by sourcing from your company in India?

A: Clients benefit from competitive pricing, comprehensive customization, adherence to global standards, and reliable export support. Our strategic location ensures prompt production and delivery worldwide.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry