Nylon Uncoiler Mandrel

Nylon Uncoiler Mandrel Specification

- Density

- 1.14 Gram per cubic centimeter(g/cm3)

- Heat Resistance

- Up to 110C

- Melting Point

- 220C

- Color Pattern

- Solid White

- Plastic Type

- Engineering Nylon (Polyamide 6/PA6)

- Tensile Strength

- 70 MPa

- UV Resistant

- Yes

- Surface Finish

- Smooth

- Type

- Uncoiler Mandrel

- Material

- Nylon

- Shaping Mode

- Injection Molding

- Length

- 450 mm

- Weight

- 2.2 kg

- Hardness

- Shore D 70

- Plastic Molding Type

- Precision Injection Molded

- Color

- White

- Size

- Standard (customizable options available)

Nylon Uncoiler Mandrel Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1000 Pieces Per Week

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Nylon Uncoiler Mandrel

Possessing rich domain expertise, we are efficiently meeting the needs of our clients by manufacturing and supplying an extensive range of Nylon Uncoiler Mandral. Features like high impact resistance, light weight and good dimensional stability have made this mandral applicable in cement, fertilizer, sugar and mining industries. Manufactured by using optimum quality of materials, our Nylon Uncoiler Mandral is hugely demanded in the market. We always focus on offering high quality products at affordable price to our respectable patrons.

Superior Engineering Nylon for Optimal Performance

Crafted from Polyamide 6 (PA6), the Nylon Uncoiler Mandrel demonstrates remarkable mechanical properties, including a density of 1.14 g/cm3 and resistance to high temperatures (up to 110C). The solid white color signifies its pure, unblended composition. The mandrel provides excellent wear resistance, making it ideal for repetitive industrial processes where durability and reliability are crucial.

Precision Molding for Consistent Results

Utilizing precision injection molding technology, each mandrel boasts a smooth surface finish and consistent dimensions. The standard size of 450 mm can be customized to suit specific requirements. This ensures seamless integration into most uncoiling systems, contributing to efficient operations and minimized downtime in high-volume settings.

Customizable Solutions with Exceptional Supplier Support

Available from a leading exporter, manufacturer, and supplier based in India, the Nylon Uncoiler Mandrel is offered in both standard and tailored specifications. The focus on customer needs, along with reliable export support, ensures this product delivers not just on quality, but also on adaptability and service.

FAQs of Nylon Uncoiler Mandrel:

Q: How is the Nylon Uncoiler Mandrel manufactured for high durability?

A: The mandrel is produced using precision injection molding with high-grade engineering nylon (PA6), resulting in a robust structure with consistent dimensions and a smooth finish. This process maximizes durability, making it suitable for intensive industrial use.Q: What applications are ideal for using this uncoiler mandrel?

A: This mandrel is designed for uncoiling and rewinding tasks in various manufacturing environments. Its strength and thermal stability make it suitable for heavy-duty industrial operations where consistent performance is essential.Q: When should I consider customizing the size of the mandrel?

A: Customization is recommended if your uncoiling system requires dimensions other than the standard 450 mm length. The manufacturer offers tailored solutions to ensure the mandrel fits perfectly within your setup, enhancing operational efficiency.Q: Where is this Nylon Uncoiler Mandrel manufactured and supplied from?

A: The mandrel is manufactured, exported, and supplied by a reputed company based in India, renowned for producing high-quality precision industrial components for global markets.Q: What is the process behind achieving the mandrels smooth surface finish?

A: The mandrels flawless surface is achieved through advanced injection molding techniques, which ensure not only structural integrity but also a consistently smooth finish, reducing friction during use and prolonging lifespan.Q: How can this mandrel benefit my manufacturing processes?

A: Its high tensile strength, UV resistance, and heat tolerance contribute to reduced maintenance needs and longer service life, which ultimately increases your operations productivity and lowers downtime.Q: Is the Nylon Uncoiler Mandrel suitable for high-temperature or outdoor environments?

A: Yes, the mandrel can withstand temperatures up to 110C and is resistant to UV rays, making it dependable for both indoor production lines and outdoor environments exposed to sunlight.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Products Category

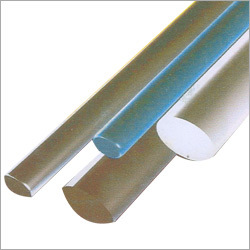

Polyethylene Terephthalate Nylon Rod

Price Range 1000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Polyethylene Terephthalate (PET)

Plastic Type : Thermoplastic

Shaping Mode : Extruded

Type : Nylon Rod

Nylon Cutting Boards

Price Range 1000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Nylon

Plastic Type : Thermoplastic Nylon

Shaping Mode : Injection Molding

Type : Cutting Board

Oilon Wear Pads

Price Range 1000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Oilon (Nylon based polymer blend)

Plastic Type : Engineering Polymer

Shaping Mode : Injection Molding

Type : Wear Pad

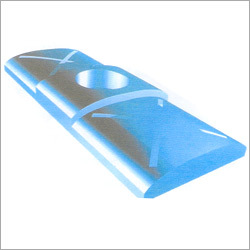

Nylon Slipper Pads

Price Range 1000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Nylon

Plastic Type : Engineering Nylon

Shaping Mode : Injection Moulding

Type : Slipper Pad

Send Inquiry

Send Inquiry